Product Development

Turn your product into Dry Molded Fiber

If you’re a brand owner, packaging manufacturer or supplier, Dry Molded Fiber opens up new possibilities for your business. And it all begins with the product. Decide which one you want, and we’ll take care of the rest.

We help you

Lead the way in responsible packaging

Whether it’s a standard product for large-scale production, limited runs of bespoke premium solutions, or future-focused R&D-driven applications, we provide packaging solutions that align with your goals and set the standard for responsible packaging. Transform your product into Dry Molded Fiber with our full support every step of the way.

standardized

A fastlane to production

Adapt existing product lines to provide responsible packaging that meets today’s demands for sustainability and convenience, while offering a scalable solution for the future.

CUSTOMIZED

Elevate your brand

Bring your unique design ideas to life with bespoke solutions. Dry Molded Fiber reflects your brand’s identity while minimizing environmental impact—ideal for limited runs and premium products.

Be inspired by bespoke and high-end Dry Molded Fiber solutions

Develop your Dry Molded Fiber product in just a few steps

With PulPac’s end-to-end application development expertise, we guide you from defining the project scope to delivering final samples. Our team ensures a seamless process at every stage of your product’s journey. Watch our video to see how we bring ideas to life with sustainable fiber-based packaging.

STANDARDIZED APPLICATIONS

Sustainable packaging to broaden your offer

Dry Molded Fiber provides a viable way to expand your portfolio with large-volume, sustainable, cost-efficient packaging. Depending on your current solution, they can improve your business case, help meet regulatory demands, and reduce CO2 emissions by up to 80%.

Cold lids

Protective lids

Hot lids

Cutlery

Trays

BUSINESS CASE INPUT

Coffee lids

CYCLE TIME (S)

3.5

OUTPUT PCS / HOUR

25 000

MATERIAL USAGE

99%

OUTPUT PCS/YEARLY

185 M

unique Design possibilities

New level of creativity in fiber-based packaging

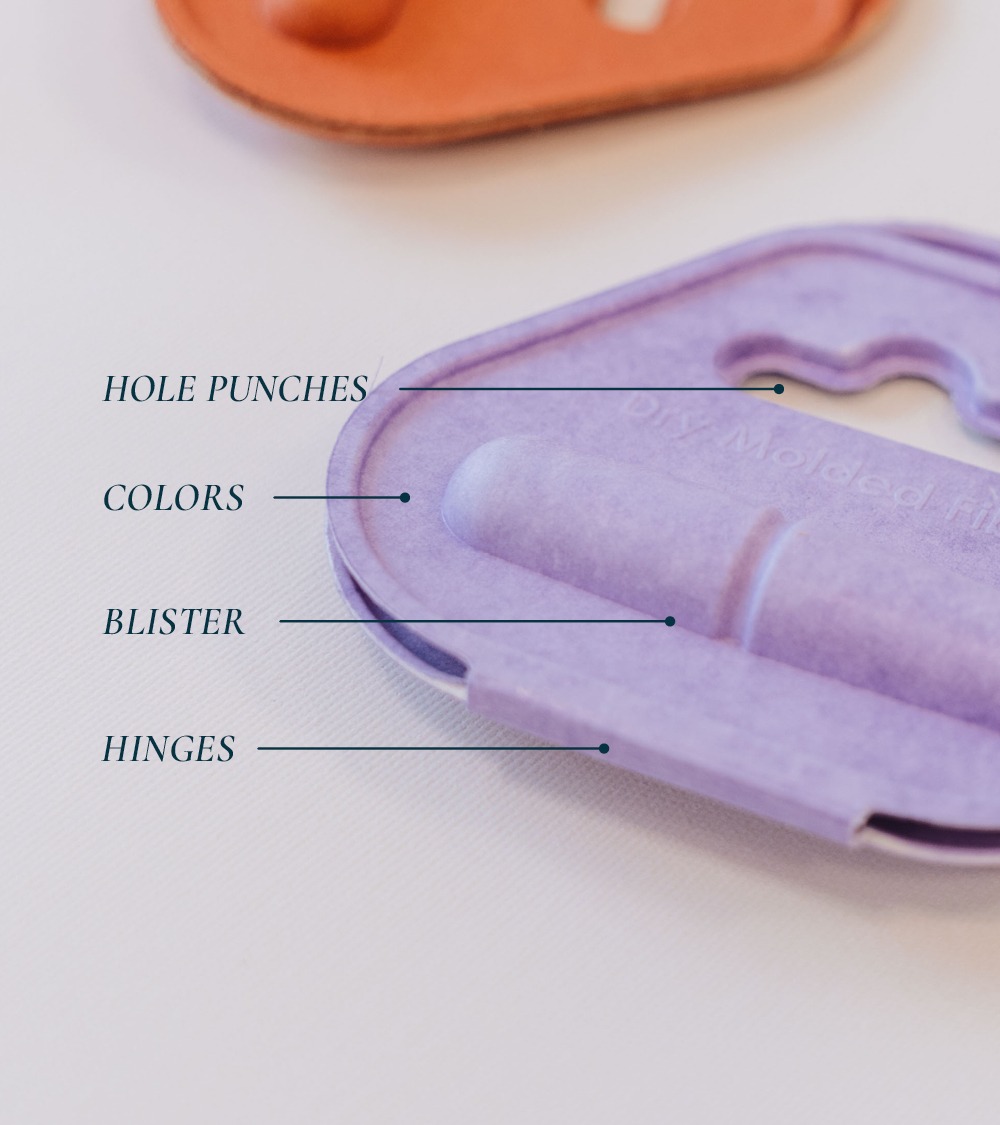

Craft packaging that elevates your brand, engages customers, and sets your product apart. Dry Molded Fiber seamlessly integrates unique design features — colors, patterns, labels, undercuts, whole punching, stacking, de-nesting, and hinges — all in one in-line stroke without additional production steps.

six steps to

Validate your product

Our streamlined application development process validates your product, provides insights on implementing Dry Molded Fiber, and offers recommendations for bringing it to market.

Product Design

Tool Design

Tool Manufacturing

Sample Production

Sample Delivery

Recommendations

What about

Deep-drawn Dry Molded Fiber products

The reason you mostly see shallow Dry Molded Fiber products is simple—they are easier to form and therefore faster to market. Deeper Dry Molded Fiber products have always been possible at lab scale, but going from the lab to industrialization obviously presents challenges. Solving these challenges is part of our ongoing R&D, included with every license. With industrialization underway, expect to see more deep-drawn products like bottles, trays, and cups.

BUSINESS CASE INPUT

Spoons

Cycle time (S)

3.5

Output pcs / hour

33 000

material usage

99%

output pcs / yearly

247 M