World’s first Dry Molded FIber pilot line

The pilot line is a sequential step toward helping licensees produce billions of completely plastic-free and degradable fiber products within a few years.

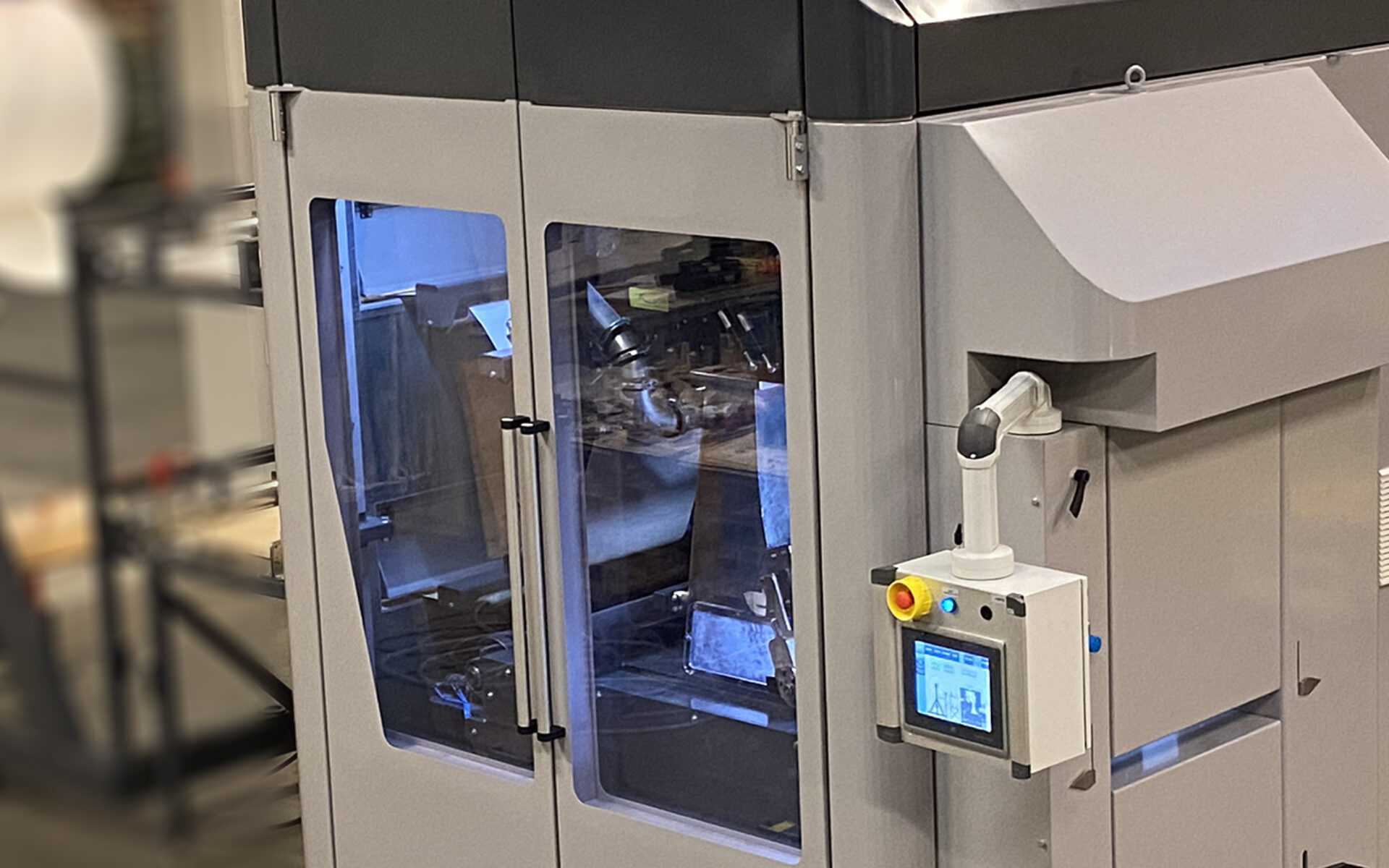

PulPac reveals world’s first Dry Molded FIber pilot line

Industrialization of the disruptive Dry Molded Fiber technology is taking off as PulPac reveals its very first pilot line. To speed up the replacement of single-use plastics globally, the company licenses the technology to manufacturers and brands setting up their own production. The pilot line is a sequential step towards the goal to help licensees produce billions of completely plastic-free and degradable fiber products within a few years.

“We have invented the first industrial method that can convert cellulose fibers into packaging that is price competitive enough to replace single-use plastics at scale. And it is possible to utilize all types of cellulose fibers, virgin, residue or recycled”,

– says Linus Larsson, CEO of PulPac.

Watch the Dry Molded Fiber pilot line at PulPac’s tech center in Sweden: https://youtu.be/UsHiZCnIrJ4

The new pilot line is fully automated. Raw paper pulp is fed through a mill to break it up into fibers. These are then formed into a web that is fed into a standard plate press. The press is equipped with unique tooling that compacts the fibers into a mold.

“Any offcuts and excess web can be fed back into the system to minimize waste. Barriers and surface decorations are easy to add in-line, rolling all manufacturing processes into one. So, there is no need for additional steps”, Larsson explains.

The industry’s interest in PulPac’s method is significant. A handful of clients and partners are already implementing the technology. The dry forming enables high-speed manufacturing of fiber products of almost any shape or use. It saves energy and reduces CO2 emissions. It also presents many design and tech advantages that traditional fiber molding methods cannot meet.

“Our clients will be able to deliver what a whole world demands, a sustainable replacement to single-use plastics – and they can do so with maintained or even increased margins in several categories. The pilot line lets us showcase the advantages of the technology and fast track industrialization for clients”, Larsson continues.

“Our vision is to be a world leader in innovative packaging that is both sustainable and commercially successful. We help clients to disrupt the industry and set a new and sustainable standard for packaging and single-use products”, Larsson concludes.

Media Contact

Linus Larsson, CEO, linus.larsson@pulpac.com, +46 (0)721 798 918

Videos

Full Video: https://youtu.be/UsHiZCnIrJ4

Short Video: https://youtu.be/xUIoRqPxlMU