New innovations extend PulPac’s IP protection

EPO announces its intention to grant a patent covering the "method of manufacturing a cellulose product having a non-flat product shape by a pressure molding apparatus comprising a forming mold."

New innovations extend PulPac’s IP protection of Dry Molded Fiber and further expand its market opportunities

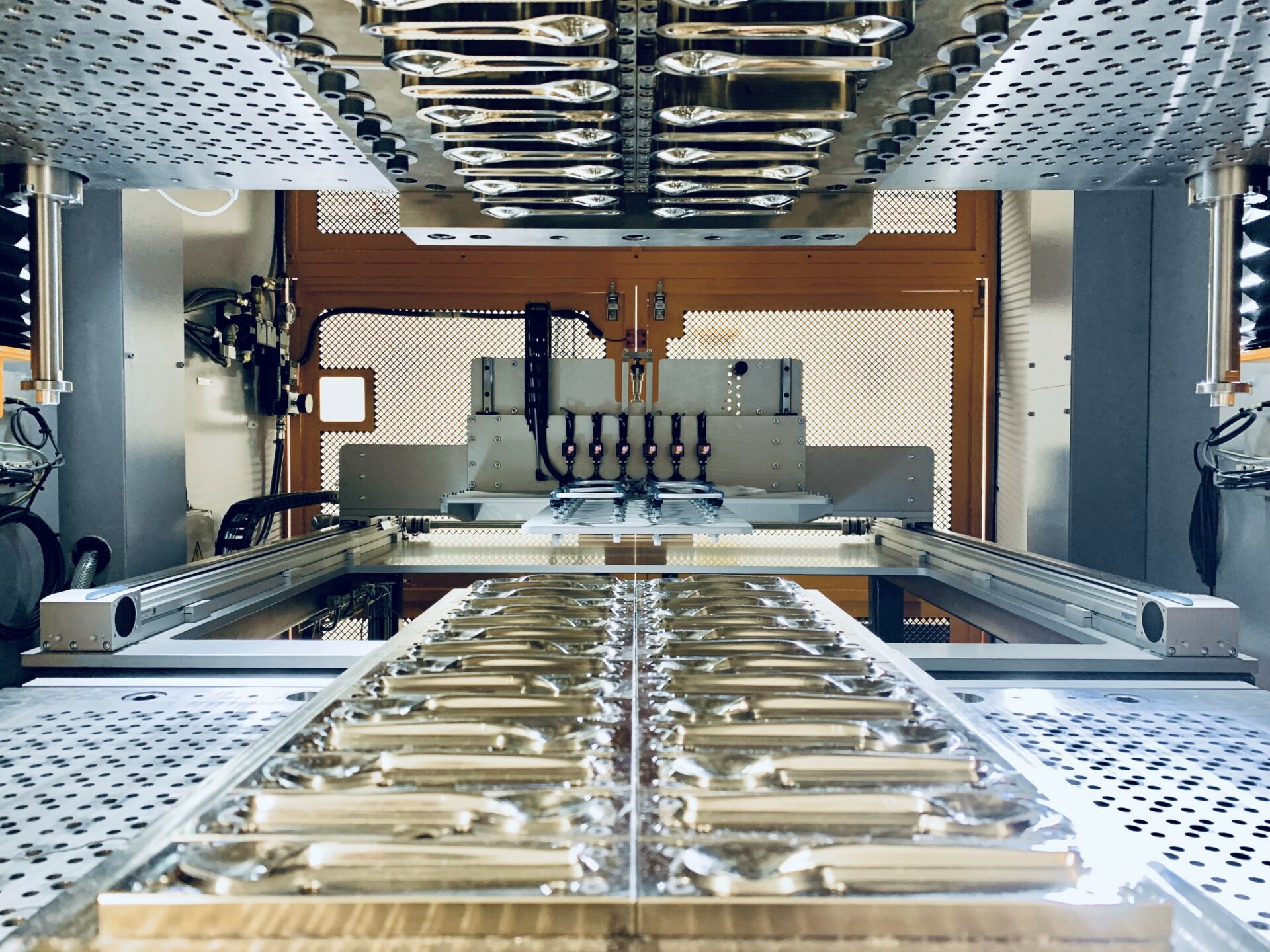

PulPac’s solid IP foundation for the Dry Molded Fiber technology keeps growing. The European Patent Office (EPO) has announced the intention to grant a patent in one of PulPac´s strategic patent families. The application covers the “method of manufacturing a cellulose product having a non-flat product shape by a pressure molding apparatus comprising a forming mold”.

This patent covers noteworthy elements in the production process and covers some of the main advantages of Dry Molding of Cellulose over conventional methods, such as wet molding or plastic thermoforming/injection molding. These benefits include (i) less energy required, (ii) zero wastewater, (iii) less or no chemical additives, and (iv) high outputs at low cost. Thus, the benefits provided enable a more efficient production of fiber-based applications with sustainable and competitive solutions for end consumers.

PulPac today has a portfolio of over 14 patent families covering various aspects of Dry Molded Fiber technology for sustainable fiber-based packaging and single-use products.

”The timing of this grant could not be better since the Dry Molded Fiber production method is receiving significant attention from major industry players. I view this grant as an important milestone, helping us to solidify our IP foundation, especially in the EU, which currently is the largest market for sustainable fiber-based packaging and single-use products”, says Ove Larsson, founder, and Chief Technology Officer at PulPac.

Media Contacts

Linus Larsson, CEO, linus.larsson@pulpac.com, +46 (0)721 798 918