SAVING THE PLANET IN STYLE

Sustainable beauty packaging

A beauty industry without plastic — is it even possible? Well, we believe it's both possible and necessary, so together with our partner, PA Consulting, we started exploring!

Sustainability should be beautiful – and beauty should be sustainable

Together with our partner PA Consulting, we explore new Dry Molded Fiber applications continuously. Recently we looked into the beauty industry and can conclude that sustainability doesn’t have to compromise beauty.

The right barriers for the right eyeshadow

Did you know that the beauty industry globally generates an astonishing 120 billion packaging units a year, equating to a whopping 70% of total beauty industry waste? Recycling accounts for just 9% of its entire packaging waste.

A challenging segment with high demands

Replacing plastic in the beauty industry poses significant challenges—it’s not only costly, but the diverse chemistries in products demand varied functional barriers. Achieving the desired brand aesthetics adds another layer of complexity, not to mention the scalability and end-of-life concerns.

The Dry Molded Fiber technology is able to address these challenges head-on. Fast, virtually dry, and offering numerous design and manufacturing advantages, it enables high-speed, low-cost production with close to zero material waste and up to 80% reduction in CO2 emissions. Moreover, it enables premium finishes, textures, embossing, debossing and decorations, ensuring brands maintain their desired look and feel.

High-end packaging with the PulPac Scala

With PulPac’s machine platform Scala, even high-end consumer packaging becomes cost-effective despite the lower volumes that are common for e.g. beauty packaging products. The reasonable machine investment and a lower cost of tooling due to fewer cavities in a more compact machine, mean that the business case quickly becomes very favorable. Effective delivery of machinery and shorter lead times for less tooling also mean a great advantage for being able to move quickly move from design to production of sustainable beauty packaging and other high-end packaging products.

Whether it’s refill systems, inserts, gift boxing, lightweighting primary packaging, or transitioning to fully paper-based solutions, Dry Molded Fiber is both ready and fit to empower brands to elevate their packaging to sustainable, premium-feel solutions.

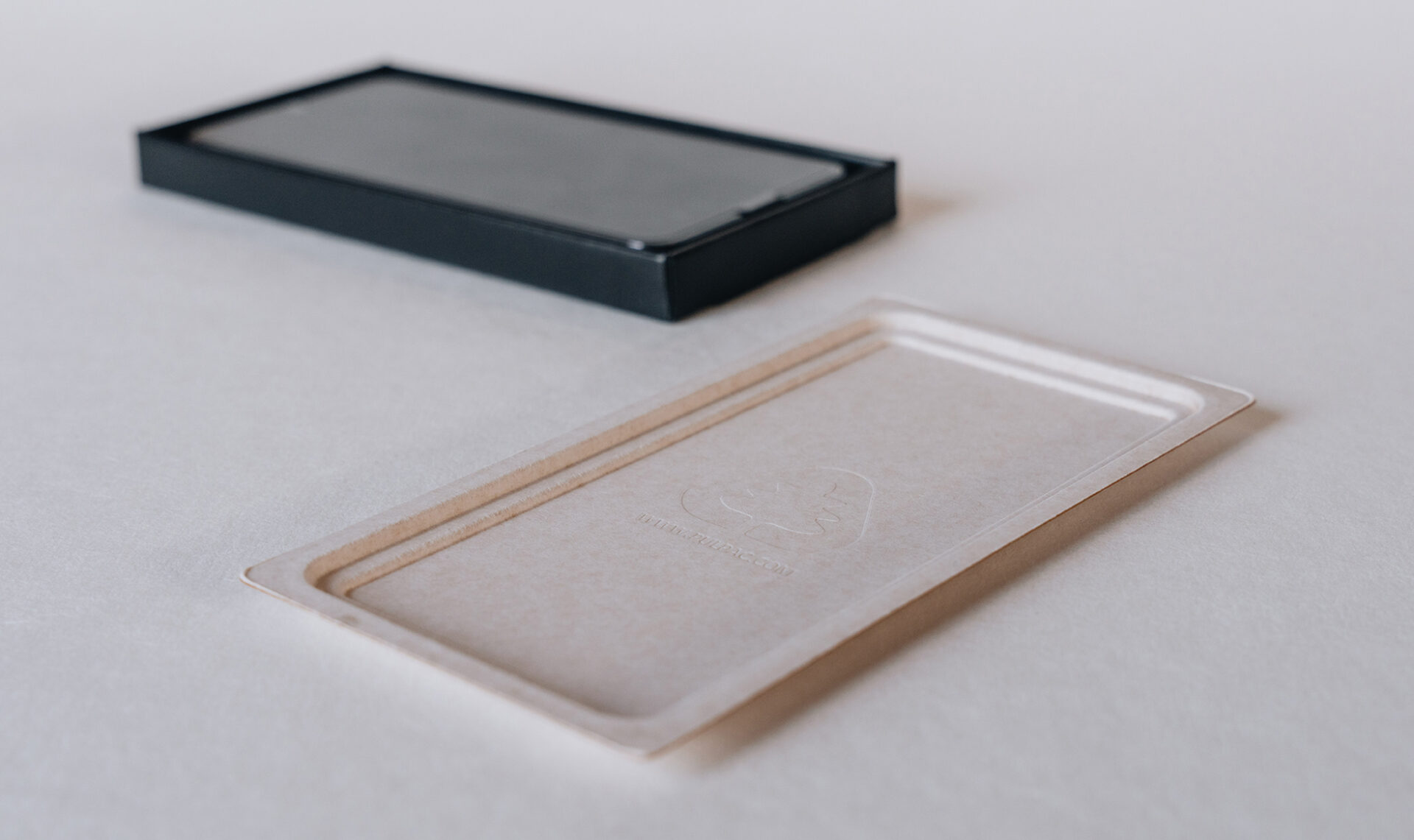

BEAUTY IN DRY MOLDED FIBER

These gorgeous little powder pot samples are designed by PA Consulting and made in Dry Molded Fiber.