PulPac and BIO-LUTIONS in joint Eurostars project

PulPac and BIO-LUTIONS reveal joint Eurostars R&D project The project, that revolves around PulPac’s unique fiber…

PulPac and BIO-LUTIONS reveal joint Eurostars R&D project

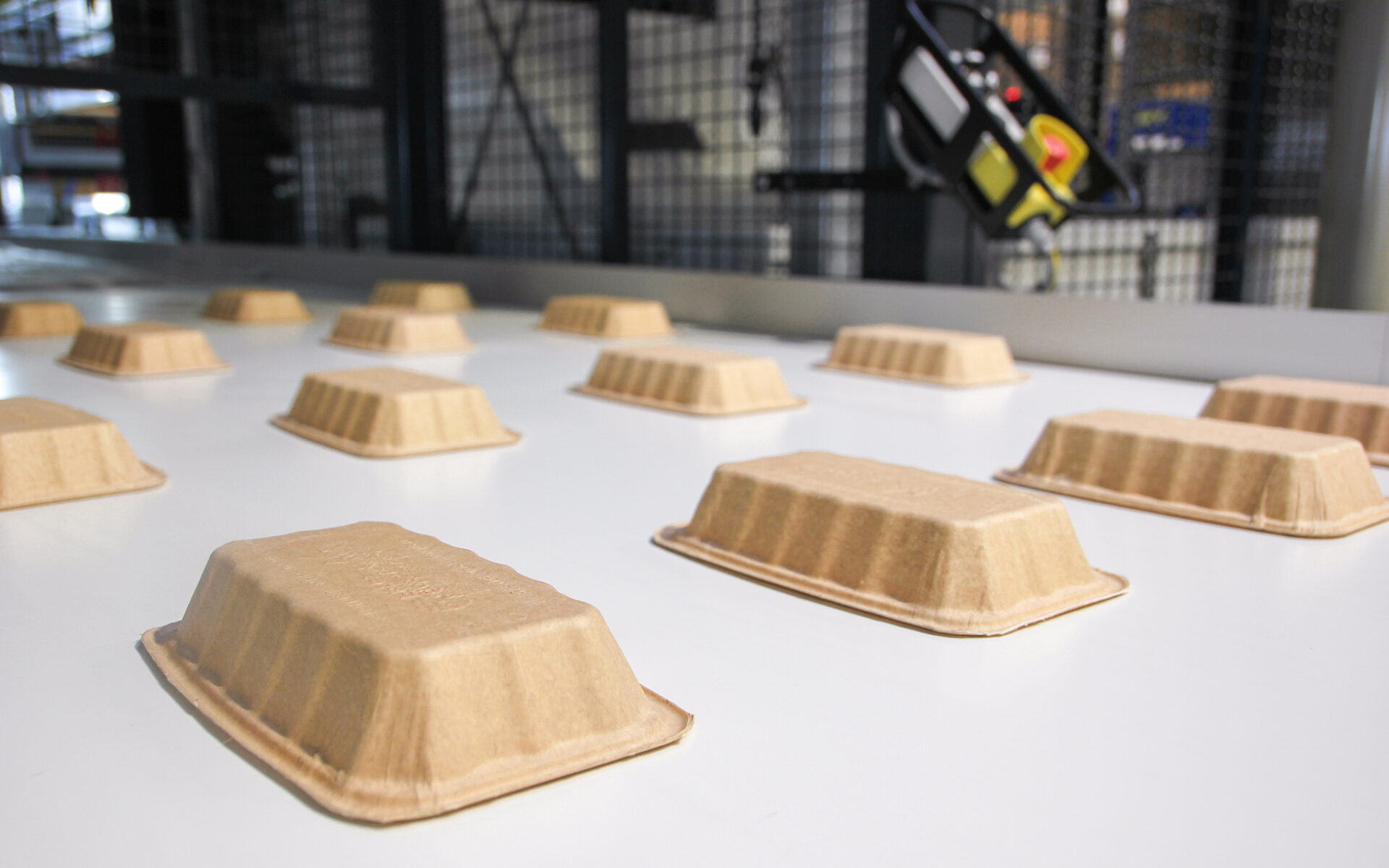

The project, that revolves around PulPac’s unique fiber forming technology and its potential to operate with fibers sourced from agricultural residues – provided by BIO-LUTIONS – has been granted financial support for cutting-edge R&D and testing, within the Eurostars innovation program.

The scope is to design, build and test a prototype of a Dry Molded Fiber machine by adapting standard components, traditionally used for production of plastic products. The aim is to validate components for international packaging markets that can use agricultural residues as inputs, besides standard pulp. PulPac will address the technical challenge, while BIO-LUTIONS will support with operational requirements and conduct pilot tests with its unique fibcro® fibers.

Ove Larsson, Chief Technology Innovation Officer at PulPac comments, “We are very excited about the Eurostars project and the opportunity to investigate how Dry Molded Fiber could utilize components from the plastic industry. Surprisingly, single-use plastic production is still growing globally, albeit with more and more products being banned by governments, and consumers demanding a shift – with cellulose fibers as the obvious solution. By widening the possibilities for Dry Molded Fiber to also include plastic-machine components, we would be able to accelerate the transition to a circular economy. Our solutions are plastic-free, biodegradable and recyclable but most importantly, cost-effective.”

“Combining BIO-LUTIONS’ fibcro® natural fibers sources from agricultural residues, and the Dry Molded Fiber process gives us unique opportunities. We are excited to be part of this R&D-project to validate and support with our operations expertise and test capacity” comments Eduardo Gordillo, CEO BIO-LUTIONS.

Eurostars is the largest international funding program for SMEs wishing to collaborate on R&D projects that create innovative products, processes, or services for commercialization.

Media contacts:

Celine Brockmann, Corporate Communications and Marketing Manager; cb@bio-lutions.com

Ann Dynehäll, Chief Corporate Communications Officer; ann.dynehall@pulpac.com

About PulPac

We are the inventors of Dry Molded Fiber. Our groundbreaking technology helps producers within the packaging industry to swiftly transition toward circularity. With our cost-competitive, fiber-based alternative, they meet the market and planet’s needs for responsibly produced packaging but also gain leverage by spearheading the industry. With a global partner network, we build a community to ensure we reach our goal of making Dry Molded Fiber the new standard.

About BIO-LUTIONS

BIO-LUTIONS is a Hamburg-based clean tech start-up that has developed its own innovative natural fibre technology, used to produce sustainable packaging and disposable tableware. The production process gives a second life to currently unused agricultural residues as raw material to replace conventional plastic and paper products. BIO-LUTIONS was founded in 2017 and is currently expanding in Asia and Europe. With the purely mechanical process BIO-LUTIONS creates stable structures and products without additional binding agents. The application of this innovative fibre technology was developed in Germany, at their technical centre in Schwedt/Oder, Brandenburg. The first factory was opened in Bangalore, India and now follows the new production facility in Schwedt/Oder, Germany. As part of the Innovation Campus Schwedt, BIO-LUTIONS is a part of the new hub for innovative technology in Brandenburg.

For more information, please visit: www.bio-lutions.com