PulPac licensee reaches industrial milestone with Dry Molded Fiber line and full automation

Another PulPac licensee has successfully commissioned a modular Dry Molded Fiber production line, complete with integrated downstream automation. The installation has passed Site Acceptance Testing (SAT) and is now running at verified industrial speed.

PulPac is pleased to share that another licensee has successfully commissioned a modular Dry Molded Fiber production line, complete with integrated downstream automation. The installation has passed Site Acceptance Testing (SAT) and is now running at verified industrial speed.

“EACH SUCCESSFUL INSTALLATION DEMONSTRATES THAT INDUSTRIAL FIBER CONVERSION IS NOT JUST POSSIBLE—IT’S HAPPENING.”

— Sanna Fager, Chief Commercial Officer at PulPac —

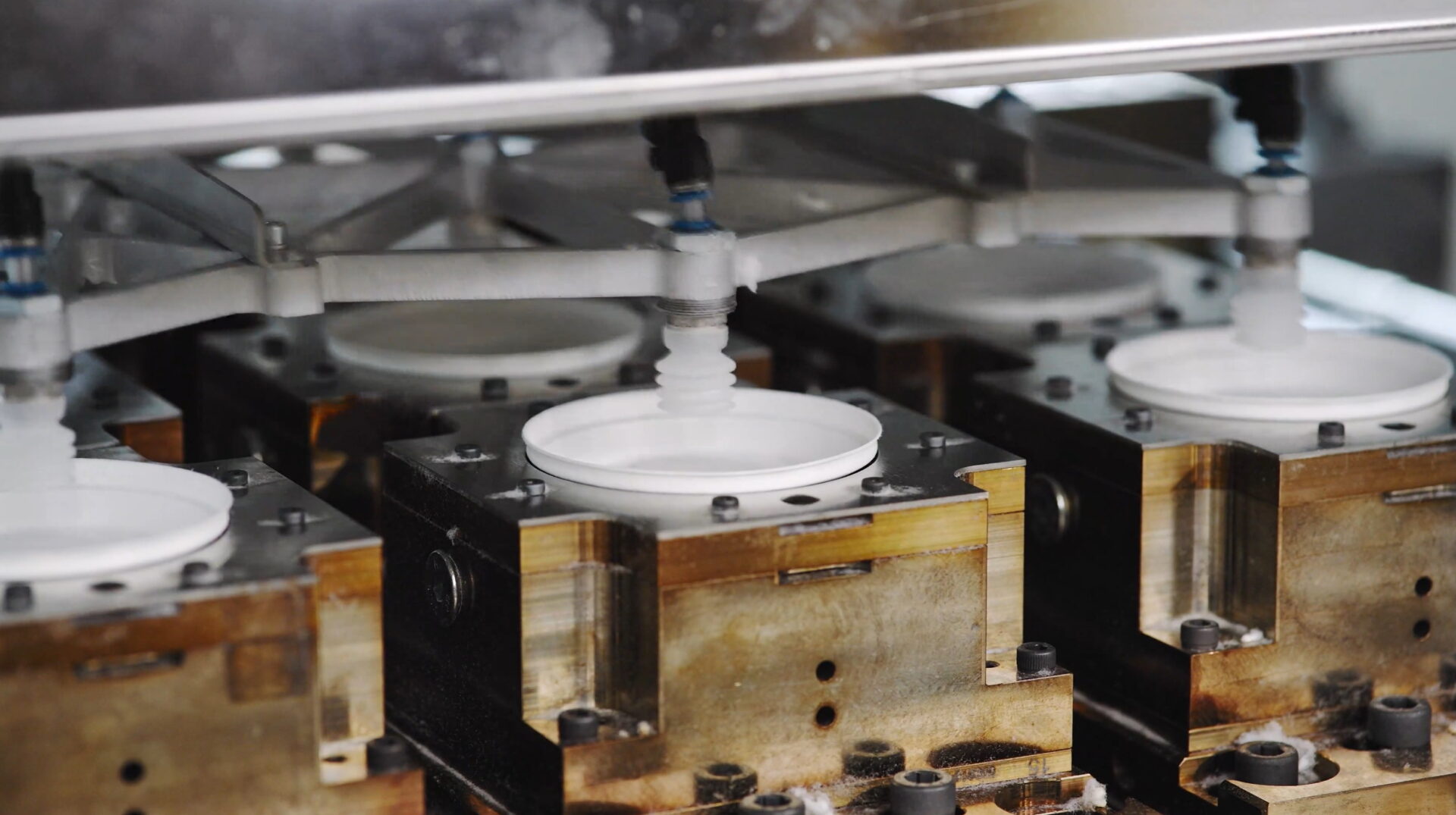

The line is operating at a sustained cycle time of 3.76 seconds, enabling a production capacity of 23,000 fiber-based lids per hour. This achievement underlines the scalability of PulPac’s modular technology platform and its ability to meet the demands of high-volume, high-performance production—while offering a resource-efficient, low-waste, fiber-based alternative to single-use plastics.

“We are delighted to see more and more partners successfully completing their SATs,” said Linus Larsson Green, CEO and Founder of PulPac. “This achievement confirms the performance of our modular platform—delivering scalable, high-speed production with the reliability and efficiency converters need to move away from single-use plastics.”

The line integrates seamlessly with automated downstream systems from lids to fully packaged box ready for distribution, enabling end-to-end efficiency and setting the standard for next-generation fiber-based packaging solutions.

“This is a clear signal of growing commercial demand for Dry Molded Fiber,” added Sanna Fager, Chief Commercial Officer at PulPac. “Each successful installation demonstrates that industrial fiber conversion is not just possible—it’s happening. We’re proud to support our licensees as they scale up, and we welcome more converters to explore how Dry Molded Fiber can strengthen their packaging offer and future-proof their operations.”