Nippon Molding accelerates Dry Molded Fiber rollout in Japan with successful machine installation

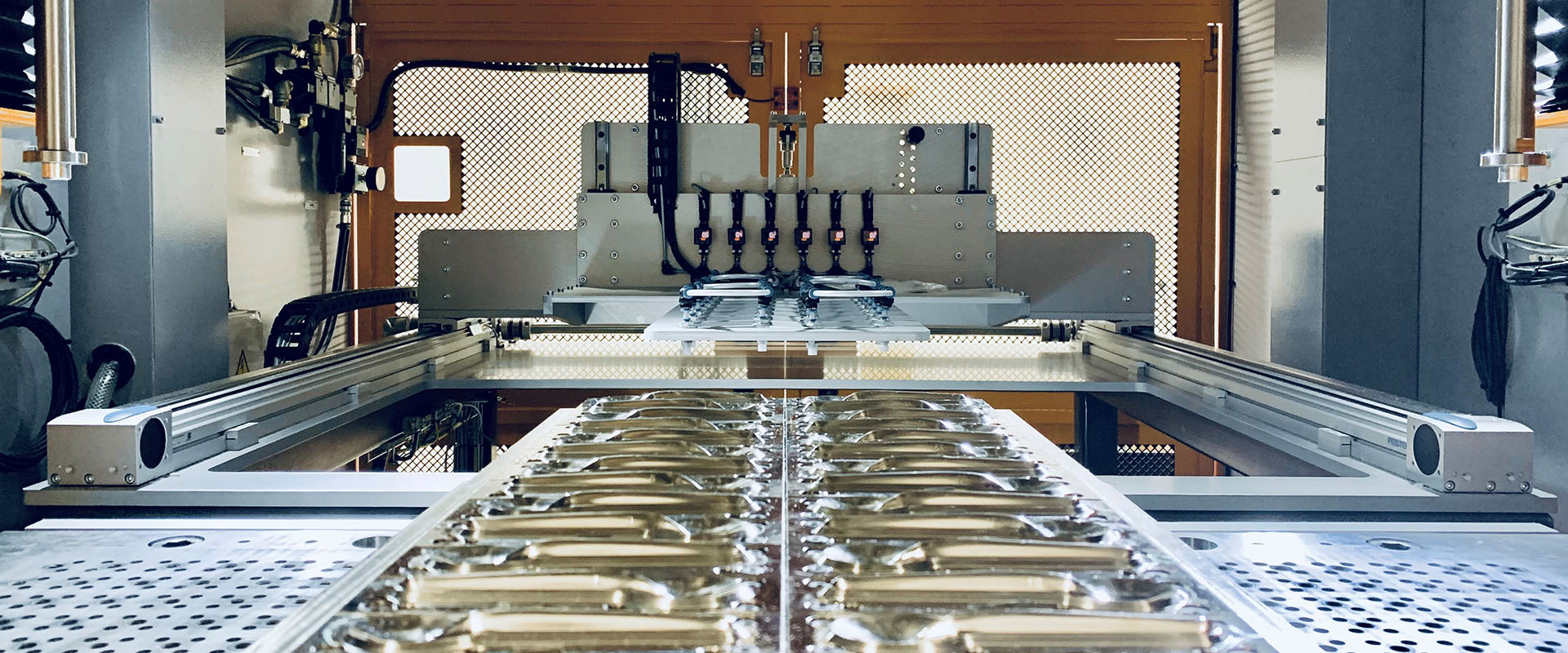

PulPac today announces a significant milestone for Dry Molded Fiber in Japan as Nippon Molding Co., Ltd. has successfully completed Site Acceptance Testing (“SAT”) of their PulPac Modula machine from TechTribe.

PulPac today announces a significant milestone for Dry Molded Fiber in Japan as Nippon Molding Co., Ltd. has successfully completed Site Acceptance Testing (“SAT”) of their PulPac Modula machine from TechTribe. As Japan seeks to cut back on its plastic waste, this achievement underscores the country’s importance as a rapidly growing market for fiber-based packaging and highlights Nippon Molding’s commitment to driving sustainable innovation.

Nippon Molding is a leading producer of egg trays for the poultry industry in Japan. With a clear mission to use limited resources effectively, the company is expanding its existing portfolio with Dry Molded Fiber, addressing the rising demand for more circular and resource-efficient packaging.

“We keep challenging ourselves for a better future and are thrilled to have finalized the SAT,” said Takehiro Ishihara, General Manager of Nippon Molding. “In parallel, we are refining our food tray application for manufacturing, to swiftly bring these sustainable solutions to our customers and further contribute to a greener society.”

As Nippon Molding expands its offering with Dry Molded Fiber, additional PulPac Modula machines from TechTribe are also advancing through SATs around the globe. Meanwhile, in Sweden, products based on PulPac’s technology have already reached the market, demonstrating the growing commercial demand of fiber-based alternatives.

“We are delighted to see more and more partners successfully completing their SATs,” said Sanna Fager, Chief Commercial Officer at PulPac. “We commend Nippon Molding for their unwavering commitment to sustainability and innovation, and we look forward to supporting their continued success as they help drive the global transition to resource-efficient, fiber-based packaging.”

Although Japan boasts some of the highest recycling rates in the world, it remains one of the biggest producers of plastic packaging waste per capita, and far from all plastic is recycled. Surrounded by water, ocean litter is top of mind among Japanese consumers —according to a McKinsey study from 2023. The country has introduced several initiatives encouraging businesses and consumers to reduce single-use plastics. Dry Molded Fiber presents a viable alternative in this market, where packaging plays a highly prominent role. By leveraging PulPac’s technology and the Modula machine platform, Nippon Molding is well-positioned to deliver high-quality, responsible packaging to the Japanese market and lead the broader industry transformation toward more circular solutions worldwide.

About Nippon Molding

Founded in 1956, Nihon Mold Industry promotes sustainability through a one-stop solution for pulp mold products—from raw material sourcing to planning, sales, production, and logistics—across Japan and Asia. With a vision to “explore the potential of paper,” the company leverages its proprietary DMF technology to offer cost-effective alternatives to plastic packaging, even for cases previously unsuitable for paper. Committed to conserving limited resources, the company strives to realize a circular economy. For additional information about Nippon Molding Co, Ltd., please visit www.mold.co.jp/eng.