Dry Molded Fiber Machinery

Production platforms engineered for impact

From high-volume production to bespoke solutions, our platforms, developed with world-leading machine builders, are engineered for efficiency, scalability and impactful results in Dry Molded Fiber manufacturing.

Dry Molded Fiber Machine Platforms

Tailored to a world ready for change

To drive the shift to sustainable packaging, we’ve partnered with the world’s leading machine builders. Together, we offer both turnkey platforms and bespoke machine solutions, designed to meet diverse production needs—whether exploring the technology, scaling up for high-volume output, or creating specialized applications. Dry Molded Fiber manufacturing has never been more accessible.

THE PULPAC MODULA

Modularity and capacity

The PulPac Modula is a versatile, modular production line designed for high-volume manufacturing. It supports both standardized applications and tailored designs, offering single-line capacity with the flexibility to adapt and scale. Perfect for producers aiming to meet large-scale demand with efficiency.

THE PULPAC SCALA

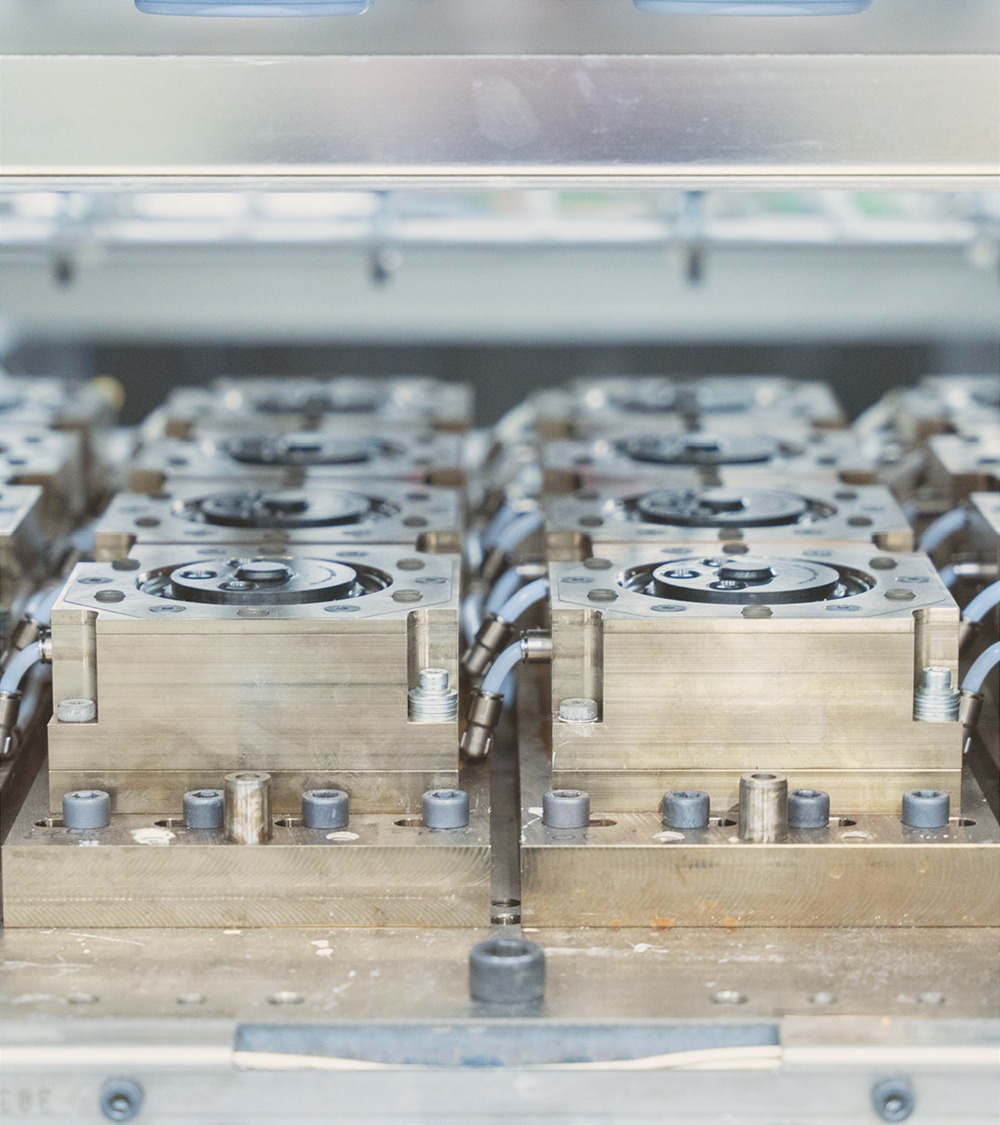

Compact but complete

The PulPac Scala, built on a plastic injection molding platform, is a compact, plug-and-play machine that delivers all the benefits of Dry Molded Fiber. The launch version is optimized for lid production, with additional applications to follow. Ideal for entering the market quickly, starting small, and scaling up as demand grows.

The PulPac Modula

Footprint

L 19.5 x W 4.1 x H 4.5m

Max. no. of cavities

24 Cold Lids

Forming area

1000 x 600mm

Press (vertical)

300 tons

Material usage

99%

The PulPac Scala

Footprint

L 9.3 x W 2.5 x H 2.8m

Max. no. of cavities

9 Cold Lids

Forming area

500 x 500mm

Press (horizontal)

300 tons

Material usage

99%

Designed for efficiency

Speed and high conversion in minimal floorspace

The PulPac Modula achieves cycle times as fast as 3.5 seconds. For products like coffee lids, it can convert up to 2.6 metric tons of pulp in 24 hours. The PulPac Scala, small yet powerful, achieves a cycle time of 3.8 seconds, converting just under 1 ton of pulp within the same timeframe. The PulPac Modula’s conversion rates are limited only by press size, allowing larger presses to further increase output.

Factory space is a critical cost factor, and our streamlined process minimizes this by transforming raw material into finished products in a single machine—no additional material preparation required.

Modula or Scala?

We’ll help you find the best fit for your needs!

What to expect from

PulPac Modula

Cycle time

3,5 s

Yearly Output up to

250M

In-line recycling

99%

PulPac scala

The power of knowledge and beauty of irony

Huarong Group has built injection molding machines for the plastic industry for 40 years. By combining that knowledge with our technology, we repurposed a machine to replace what it was once built to produce.

— Learn more about the development of Scala from Steve Yu, Overseas Sales Manager, Huarong Group

How to start dry molding?

We’ll take you through the license process and set agreements up. When you’re ready for it, our turnkey partners are the one-stop shops that take orders, assemble the machines, deliver them, and help you get the most out of your equipment.