Welcome

to the home ofDry Molded Fiber

Step into the future of responsible packaging! Explore how our innovative technology unlocks cutting-edge solutions that meet today’s needs for convenience while advancing sustainable practices and driving circularity in the packaging industry.

Revolutionizing packaging

Dry Molded Fiber empowers packaging manufacturers and brands to create responsible, innovative solutions. Together, we can transform globally available, renewable raw materials into cost-effective, resource-efficient, recyclable, compostable, and biodegradable packaging.

Convenience & Sustainability

Innovation with a purpose

The Dry Molded FIber technology is designed to reduce environmental impact without compromising on cost or performance—an ideal solution for companies seeking alternatives to single-use plastics or looking to expand their fiber-based packaging range.

Discover

The many benefits of Dry Molded Fiber

Besides sustainability, there’s a unique combination of advantages with Dry Molded Fiber— whether for high-volume production, unique customer orders, specific design needs, or optimizing factory footprint.

High Output

Fast, clean and low-noise production

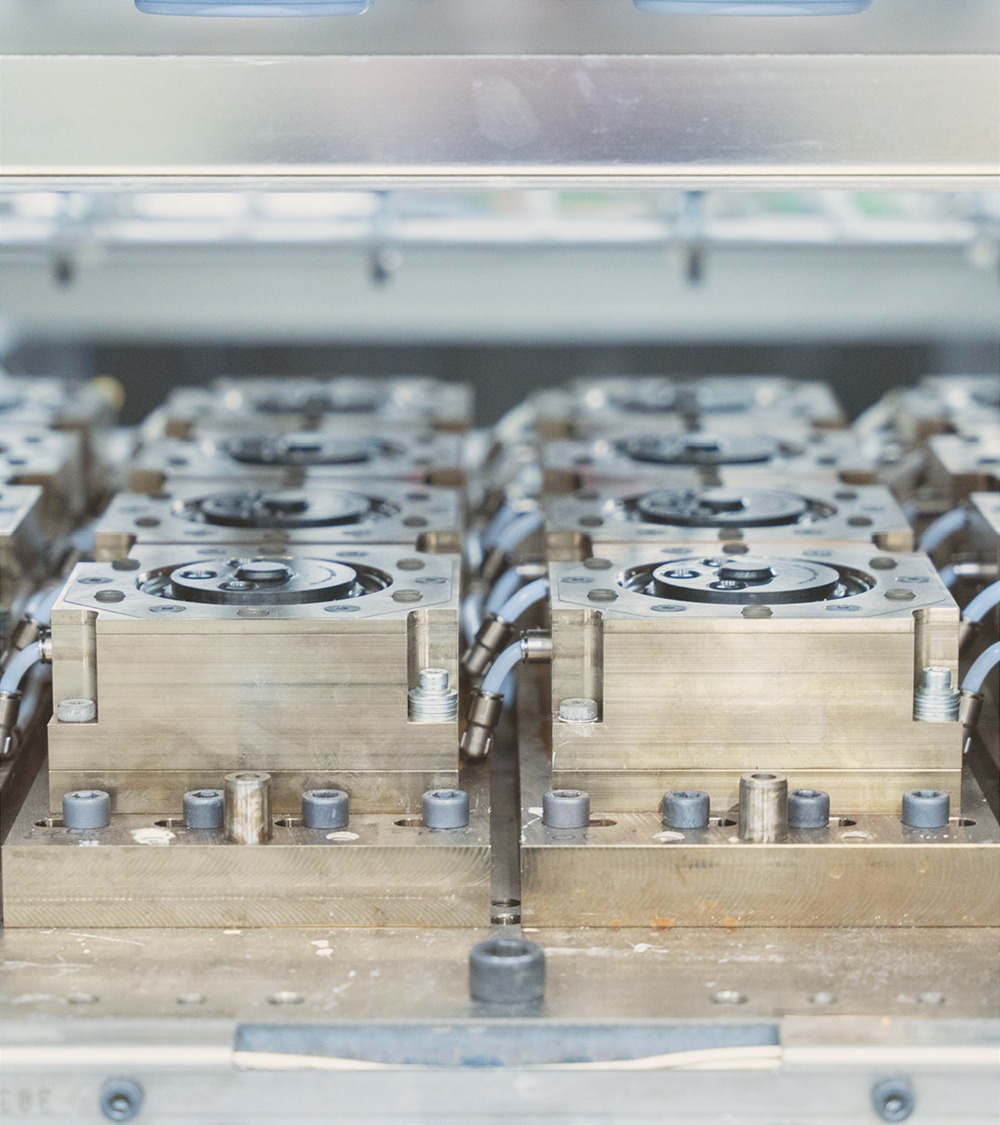

With optimized factory footprint, cycle times of 3.5 seconds in the PulPac Modula and 3.8 seconds in the PulPac Scala, you get rapid and efficient production.

reducing co2

Up to 80% lower carbon footprint

Minimal water and energy use, while maximizing raw material efficiency cuts CO2 emissions dramatically compared to alternatives.

LEAD THE SHIFT

Responsibly produced fiber-based packaging

Whether you’re a brand owner, packaging supplier, manufacturer, or part of the broader packaging supply chain, Dry Molded Fiber creates opportunities for your business.

IN THE MEDIA

PulPac in L’Oréal’s L’acceleratOR programme

PulPac is selected as one of the change makers showing the highest potential to address next generation packaging.

Advancing Dry Molded Fiber

NBCo joins the Bottle Collective

NBCo, a sustainable solutions provider specializing in fiber materials, aim to explore Dry Molded Fiber bottles in beauty and personal care.